Permanent Metal Repair Paste

Introduction

Permanent Metal Repair Paste: –

Metal is surrounding us, utilized in everything from large hardware to domestic devices and decorative objects. The metal paste is an extraordinary method to join metal to metal or metal to different materials. For most regular circumstances and simple Do-It-Yourself projects, a liquid adhesive or paste for metal is the best solution..

Each and every individual who works with metal, from metal workers and mechanics to jewelers and specialists, know paste metal necessities, and great planning. In contrast to paper, wood, or other permeable materials, the thick, smooth surfaces of metal can resist most household pastes, bringing about weak bonds and damaged items.

What is Permanent Metal Repair Paste?

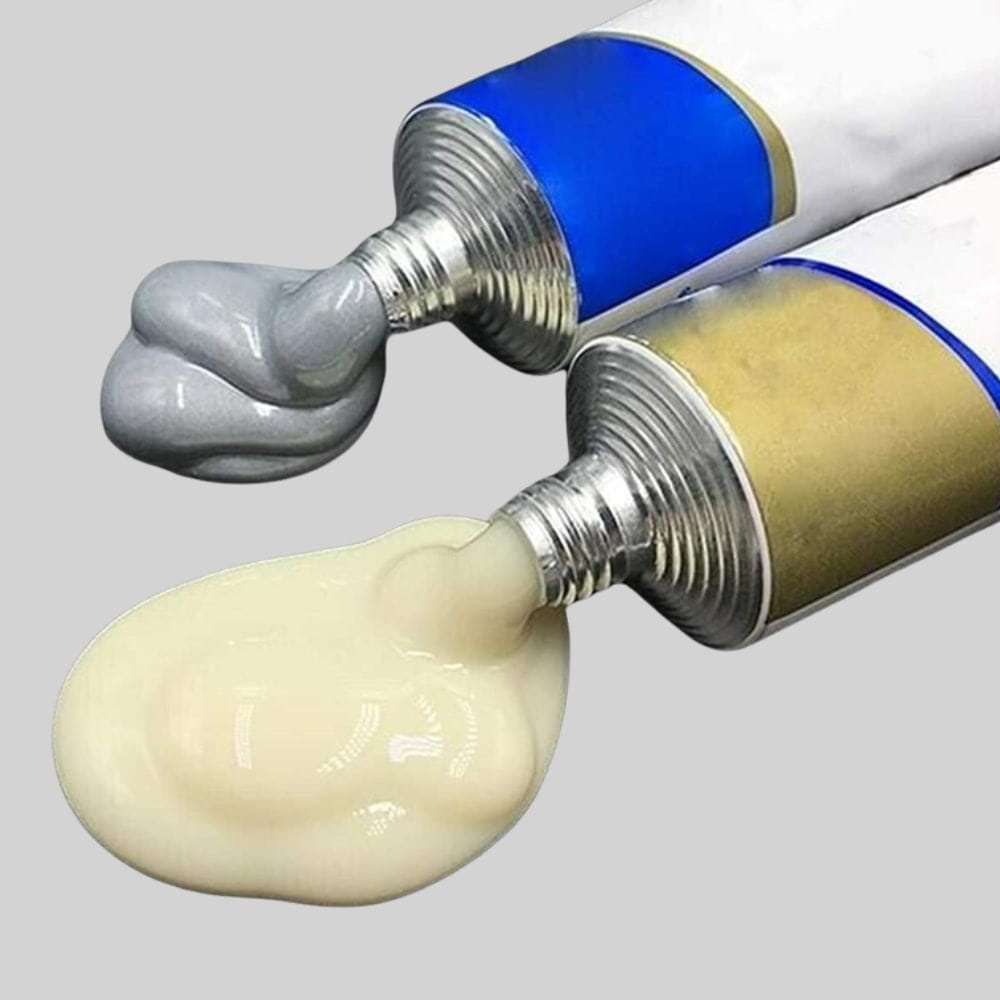

Permanent Metal repair paste is an option in contrast to welding. Its industrial-strength adhesive and fast-drying features permit bonding and repairing iron, steel, and different metals. It gives a waterproof, non-combustible, and corrosive resistance result. Whenever it’s set, it’s ready to be drilled, sanded, tapped, and so on. They are easy to Utilize. In the wake of blending, it frames a super durable bond and can be formed, tapped, recorded, sanded, and penetrated subsequent to relieving. It has a 1:1 blending proportion, sets in 6 minutes, and is completely restored in 4-6 hours. Prior to utilizing the paste, clean and dry the surface and your work ought to be finished in something like 20 minutes subsequent to blending.

How to Bond Permanent Metal with the Paste (step-by-step instructions)

1. Preparations

It is recommended to work in ventilated region or workshop that offers sufficient room to deal with all necessary materials. Utilize protective materials or papers to conceal furniture. Analyze the parts to be joined and test the fit.

2. Clean the Metal

Surfaces should be clean and dry. Eliminate any dust, dirt, wax, oil, or grease, including fingerprints, from all parts with a cloth. You may want to somewhat roughen smooth surfaces utilizing fine-grit sandpaper.

3. Apply the Metal Paste

Make sure to read your product instructions for any subtleties on application and drying times prior to beginning. Open the product cap and apply the metal paste to the prepared surface. Adhere to the instructions on the packaging for amounts. Paste requires around one drop for each square inch of surface. Many epoxy metal pastes require mixing adhesive and hardener components, then, at that point, applying with a specialized tool.

4. Join the Pieces

Position the pieces and press them together firmly to guarantee a tight seal without gaps. Leave parts undisturbed as the bond structures.

Benefits of Permanent Metal Repair Paste

A) Effective Adhesive Agent

It is developed as an alternative to torch Welding, It provides strong and long-lasting repairs to metals and numerous surfaces. It Will Bond Practically Any clean surface that is free of dirt and Oil. They likewise have a financially savvy solutions for an extensive variety of maintenance problems.

B) Simple to Use

Subsequent to blending, it forms an enduring bond and can be shaped, tapped, filed, sanded, and bored following restoration. It has a 1:1 mixing proportion, sets in 6 minutes, and is totally relived in 4-6 hours. Prior to using the paste, clean and dry the surface and your work should be finished at least 20 minutes subsequent to blending.

C) Do it Yourself

Small or big, you could DIY it with this magic welding paste. Heavy-duty epoxy and adhesives repair and restore it right at the initial time.

D) Wide Use

It is essentially Utilized for Iron and Steel casting, Sand filing and Pores, and filling of casting imperfections Such as cracks. Repair fuel Can Be utilized.

E) High-Temperature Resistant

It can endure or withstand temperatures up to 150°C. When completely relived, it is just similarly hard as iron and provides uniform bond line thickness.

F) Quickly Seal Your Chips And Gaps

Incredible for assembling things into one spot, maintenance and support, construction, crafting, and for both manufacturing and engineering purposes. Ideal for Do-It-Yourself household, auto, marine, craft repair, and considerably more. It very well may be utilized as an adhesive, laminate, plug, filler, sealant, and electrical insulator. Tanks, Plumbing, and a lot More. It permits fast and effective repairs to mechanical components.

Explicitly designed for metallic surfaces, this product is perfect for emergency repairs or part of planned maintenance equipment, for example, worn or damaged pump shafts, cracked pump o scored hydraulic rams, damaged flanges, leaking tank seams, and cracked engine blocks.

What are the Features of Permanent Metal Repair Paste?

- It provides a strong and long-lasting repair for metal and numerous surfaces. After blending, it forms an extremely durable bond and can be shaped, tapped, filed, sanded, and drilled in the wake of restoration.

- It is impervious to high and low temperatures, can be utilized in four seasons, and can endure temperatures up to 200°C.

- Fixing repairs, wear, defects, corrosion, and break of different metal castings and parts is broadly utilized.

- It has a good bonding effect, simple and convenient to apply.

- It is suitable for metal, plastic, concrete, wood, ceramics, glass, and many more from there.

- It is portable and compact, simple to store, use and convey.

Conclusion

Prior to applying permanent Metal repair paste, surfaces ought to be free of paint, rust, and grime prior to being roughened up through either grit blasting or grinding with a coarse wheel or abrasive disk pad. Full instructions specifying the preparation process can be found on the Specialized data Sheet and are provided with the product. Professional construction workers utilize this formula for its remarkable strength, long open assembly time, excellent application and unrivaled creep resistance. It can withstand up to 160°C/ – 60°C and can be drilled, tapped, filed, machined, sanded, and painted once completely restored. Permanent Metal repair paste ought to be applied when the preparation procedure is completed. The epoxy paste is then spread over the area requiring a fix utilizing a clay blade. Permanent Metal repair paste ought to be pushed in firmly to ensure maximum contact and to try not to avoid trapping air between the paste and the surface.